Menu

At Ceramed, we take pride in offering you a comprehensive range of high-quality coating services designed to meet your most demanding needs. Our expertise is reflected in three key areas: Plasma, PVD, and Anodization.

Explore this range of services and see how Ceramed can transform your products and components to make them more efficient and durable, achieving the excellence they deserve.

We are wholeheartedly committed to spreading care and concern to communities and individuals in an effort to improve quality of life.

Our plasma spray coating service provides advanced technology to exceptionally strengthen and protect your objects. By using high temperatures, we apply a special layer that enhances the resistance, durability, and performance of your objects, making them more robust and long-lasting. The goal is to turn your products into superior quality items, ready to meet all the challenges posed by the medical industry today.

The Hydroxyapatite (HAp) plasma coating process involves depositing a thin layer of

hydroxyapatite onto the surface of medical implants, such as joint or dental prostheses,

using a plasma spray process.

Benefits:

Hydroxyapatite coating has a composition like that of human bone, promoting its

natural integration into bone tissue. It encourages bone growth around the implant,

making it stable and durable. It reduces post-operative pain, accelerates patient

recovery, and allows better mobility. It acts as a barrier between the implant material

(usually metal) and the body, limiting the release of potentially harmful metal ions. It

resists dissolution when in contact with bodily fluids. It can also be modified to have

antibacterial properties, helping to prevent post-operative infections.

Hydroxyapatite Plasma Coating is a process that coats medical implants with a bone-like

material, promoting integration into bone tissue, improving implant durability, and

reducing post-operative complications.

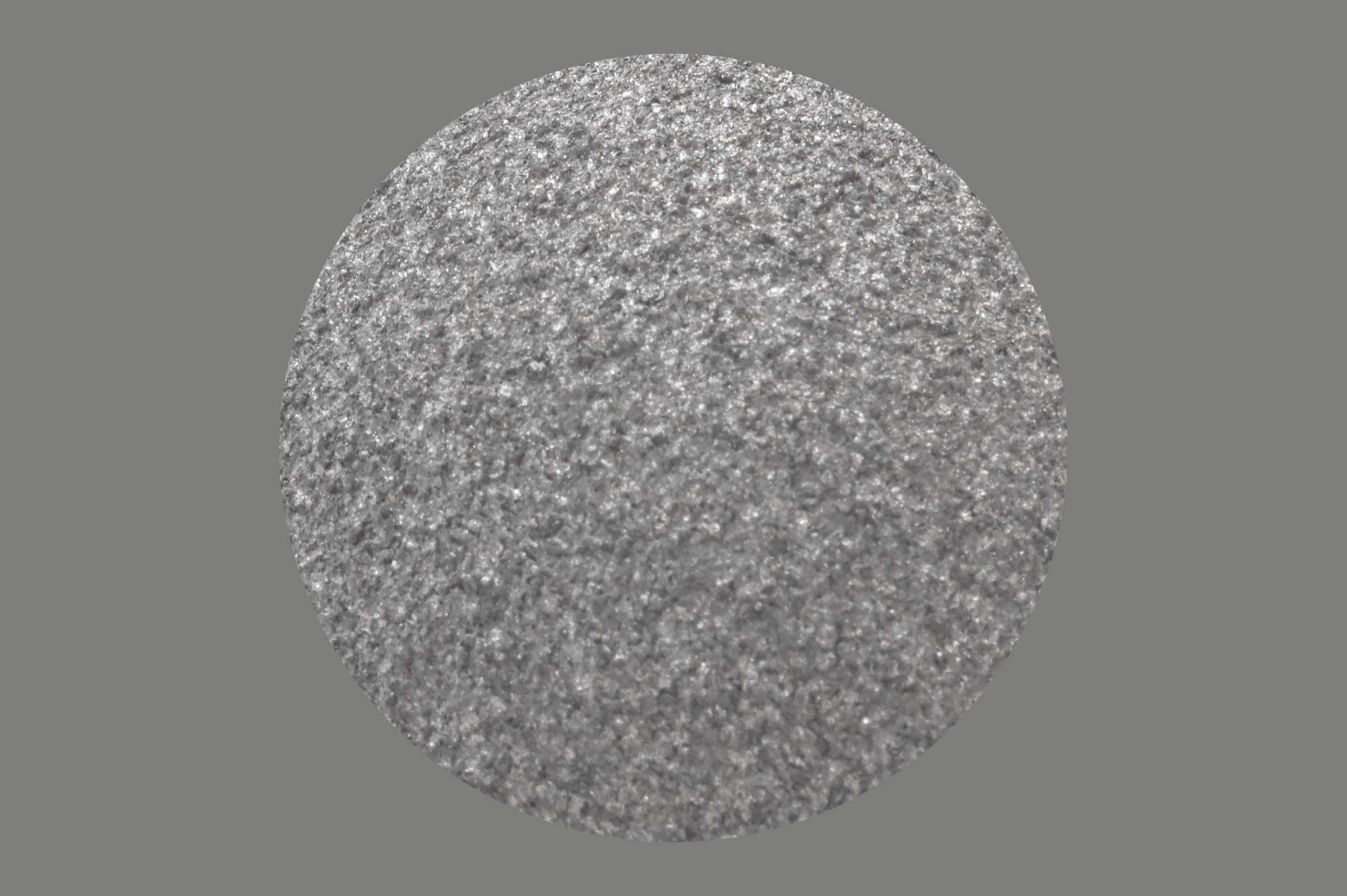

The titanium plasma coating process involves applying a thin layer of titanium to a

metal surface to enhance its properties.

Benefits:

Titanium coating enhances the surface properties of metal, such as corrosion resistance,

wear resistance, and more. It is used to increase the durability and performance of your

parts, improving the wear resistance of medical implants and strengthening their

durability. Titanium coating is porous and rough, allowing bone tissue to grow into the

coating voids, creating a strong bond between the implant and bone while reducing

pressure at the interface between the two.

Titanium plasma coating involves spraying molten titanium onto a metal surface using

hot plasma. This process enhances surface properties, allowing for a strong natural

bond between the implant and bone, while also reinforcing and protecting the parts.

Benefits:

The Ti layer provides mechanical strength and initial stability to the implant. It's rough

and porous surface allows better attachment and osseointegration. The HAp layer

enhances implant bioactivity, encouraging the deposition of calcium phosphate, a key component of natural bone, on the implant's surface. This promotes faster bone regeneration and better bonding with the implant. The combination of Ti and HAp leverages the strengths of both materials: the mechanical properties of Ti and the bioactivity of HAp. This combination enhances the

integration of medical implants with the patient's bone tissue, promoting faster and stronger fixation, ultimately improving the overall success of implantation surgeries.

The PVD (Physical Vapor Deposition) coating process is a technique for depositing very

thin layers of materials, such as titanium nitride (TiN) or titanium-niobium nitride

(TiNbN), onto objects like surgical instruments or medical implants.

Benefits:

High Hardness: PVD coating increases the hardness of the object, making it more

resistant to wear and abrasion.

Low Friction Coefficient: It reduces friction, allowing cutting instruments to perform

better and last longer.

Protection Against Harsh Environments: The coating provides an effective barrier

against chemicals or corrosive liquids, preserving the object's integrity.

Biocompatibility: It is compatible with the human body, minimizing the risk of allergies

or rejection when used in medical implants or surgical tools during procedures.

Prevention of Material Diffusion: It prevents the diffusion of implant materials into

surrounding tissues, ensuring patient safety. PVD coating is a technique that enhances the performance and durability of objects by

covering them with a thin, robust layer of material, making them more suitable for

medical applications, especially for surgical instruments and implants.

The anodization process is a technique for creating a protective oxide layer on the

surface of materials.

Gray Anodization :

Gray anodization is an anodization process that creates a gray aluminum oxide layer on

the surface of aluminum. It provides corrosion protection and enhances aluminum's

wear resistance..

Colored Anodization :

To make the oxide layer more stable, titanium can undergo anodization treatment with

a thicker oxide layer. This process allows customization of the appearance of aluminum

parts, offering a range of aesthetic shades and finishes. It also retains the basic benefits

of anodization, such as corrosion protection, increased durability, and improved wear

resistance.

Benefits:

Anodization provides several advantages to aluminum pieces:

Corrosion Protection The oxide layer created by anodization shields aluminum from

corrosion by preventing oxygen and moisture from penetrating the material.

Increased Durability It enhances the wear resistance of the piece, making it harder and

more scratch resistant.

Electrical Insulation The oxide layer can also serve as electrical insulation in some

applications.

Aesthetics Anodization can be used to color the surface of aluminum, offering design

and aesthetic options.

In summary, anodization is a process that creates a protective oxide layer on the surface

of aluminum, improving its corrosion resistance, durability, and properties.

The anodization process is a technique for creating a protective oxide layer on the surface of materials.

The PVD (Physical Vapor Deposition) coating is a technique for depositing very thin layers of materials, such as titanium nitride (TiN) or titanium-niobium nitride (TiNbN), onto objects like surgical instruments or medical implants.

Benefits:

PVD coating increases the hardness of the object, making it more resistant to wear and abrasion.

It reduces friction, allowing cutting instruments to perform better and last longer.

The coating provides an effective barrier against chemicals or corrosive liquids, preserving the object's integrity.

It is compatible with the human body, minimizing the risk of allergies or rejection when used in medical implants or surgical tools during procedures.

It prevents the diffusion of implant materials into surrounding tissues, ensuring patient safety.

PVD coating is a technique that enhances the performance and durability of objects by covering them with a thin, robust layer of material, making them more suitable for medical applications, especially for surgical instruments and implants.

The Hydroxyapatite (HAp) plasma coating process involves depositing a thin layer of hydroxyapatite onto the surface of medical implants, such as joint or dental prostheses, using a plasma spray process.

Benefits:

Hydroxyapatite coating has a composition like that of human bone, promoting its natural integration into bone tissue. It encourages bone growth around the implant, making it stable and durable. It reduces post-operative pain, accelerates patient recovery, and allows better mobility. It acts as a barrier between the implant material (usually metal) and the body, limiting the release of potentially harmful metal ions. It resists dissolution when in contact with bodily fluids. It can also be modified to have antibacterial properties, helping to prevent post-operative infections. Hydroxyapatite Plasma Coating is a process that coats medical implants with a bone-like material, promoting integration into bone tissue, improving implant durability, and reducing post-operative complications.

The titanium plasma coating process involves applying a thin layer of titanium to a metal surface to enhance its properties.

Benefits:

Titanium coating enhances the surface properties of metal, such as corrosion resistance, wear resistance, and more. It is used to increase the durability and performance of your parts, improving the wear resistance of medical implants and strengthening their durability. Titanium coating is porous and rough, allowing bone tissue to grow into the coating voids, creating a strong bond between the implant and bone while reducing pressure at the interface between the two. Titanium plasma coating involves spraying molten titanium onto a metal surface using hot plasma. This process enhances surface properties, allowing for a strong natural bond between the implant and bone, while also reinforcing and protecting the parts.

Benefits:

The Ti layer provides mechanical strength and initial stability to the implant. It’s rough and porous surface allows better attachment and osseointegration. The HAp layer enhances implant bioactivity, encouraging the deposition of calcium phosphate, a key component of natural bone, on the implant’s surface. This promotes faster bone regeneration and better bonding with the implant. The combination of Ti and HAp leverages the strengths of both materials: the mechanical properties of Ti and the bioactivity of HAp. This combination enhances the integration of medical implants with the patient’s bone tissue, promoting faster and stronger fixation, ultimately improving the overall success of implantation surgeries.

Benefits:

Anodization provides several advantages to aluminum pieces: Corrosion Protection The oxide layer created by anodization shields aluminum from corrosion by preventing oxygen and moisture from penetrating the material. Increased Durability It enhances the wear resistance of the piece, making it harder and more scratch resistant. Electrical Insulation The oxide layer can also serve as electrical insulation in some applications. Aesthetics Anodization can be used to color the surface of aluminum, offering design and aesthetic options. In summary, anodization is a process that creates a protective oxide layer on the surface of aluminum, improving its corrosion resistance, durability, and properties.